Friday, 12 November 2010

yay! dont you just love payday!

well, pay day is upon us, well its been a few days and aftre sorting out all my other bits ni need to buy, i decieded to put money towards a mk5 and a few other bit and pieces for the makerbot... so putting in my order, i am dreading the cost of uk import tax... estimate it to be about £50 so when it comes i will let you know, but... it has been ordered!

for some reason i cant add a pic... but the total cost was $259.70, thats about £158.

i got:

mk5 plastruder full kit: $185 (£114.42)

2 x lengths of nichrome to replace mk4 bits: $10 (£6.18)

frostruder mk2 experimenters kit - to use on my pcb smt setup: $20 (£12.37)

10 x 3mm gold magnets: $2.50 (£1.54)

and postage: $42.20 (£26.10)

we shall see! its been shipped along with some timing belts to replace the ones i have originally, they were open ended belts glued together with wet suit glue so will eventully break!

but yay,

need to also buy a new stepper motor chip...

for some reason i cant add a pic... but the total cost was $259.70, thats about £158.

i got:

mk5 plastruder full kit: $185 (£114.42)

2 x lengths of nichrome to replace mk4 bits: $10 (£6.18)

frostruder mk2 experimenters kit - to use on my pcb smt setup: $20 (£12.37)

10 x 3mm gold magnets: $2.50 (£1.54)

and postage: $42.20 (£26.10)

we shall see! its been shipped along with some timing belts to replace the ones i have originally, they were open ended belts glued together with wet suit glue so will eventully break!

but yay,

need to also buy a new stepper motor chip...

Friday, 22 October 2010

Blue magic smoke :(

So, here it is... as im designing a shell for use in a project, which needs to be completed by Wednesday... for the MCM expo! Yes the MCM expo in london next weekend, i go to use my makerbot, and sadly the Z axis starts playing up... then a wiff, snap crackle and pop (and no mini cartoon characters to see for miles) the stepper motor controller decieds to frazzle.

Luckily when the first time this happened, i ordered 2 spare chips, so i can replace the chip, will just take time...

Here goes!

Luckily when the first time this happened, i ordered 2 spare chips, so i can replace the chip, will just take time...

Here goes!

Wednesday, 20 October 2010

Building of wobble arrester and new cable

Well its been an eventfull couple of weeks.

firtly i decieded to change my usb ttl adapter for the makerbot to a 5v logic level, as apposed tothe 3.3v logic level one i was using. the idea behind this was that the switchover signal voltage could have been too low and therefore meant the data was not being sent at good quality. I was annoyed when i bought the first cable, as i was thinking it was a 5v level cable, but alas... oh well.

the first tests came as i was setting up the uni makerbot for a demo of high calibre... more on that in a sec, but i managed to start repg and the new software version, meaning i could import and manipulate the files stl etc in repg.

the first trial pieces were done using my pc desktop, an old pentium 4. (i now bought a i5 HP laptop, so yay!) I did wounder if the processing speed was too slow for the makerbot, and i think i might have been right...

anyway, my first prints using the 5v cable, turned out to be good. they were a corner bracket, to try simple shapes... and then the z wobble arrester. this is an amazing thing an im glad i printed it, as my sides are virtually wobble free (need a second one for other side of rear as that too is a bit wobbly...

anyhow, i printed these with great success, installed the wob arr and set to print something more complex. The gear set, recently uploaded seemd lie the perfetc vhoice.

link here :(insert link)

the results seemed ok, but the thinner smaller gear had to be height adjusted as too much plastic was comming out causing lumps. - this maybe because there wasnt enough time to cool befre the heater nozel came ploughing through, so need to work on 'cool' settings as mentioned in recent blog post elsewhere - should really write the links down!. need to adjust speed and extruder flow rate too, both adjust this issue.

right a picture...

or 2...

the L bracket, shows several wobbly edges so off to print the z wobble arrester...

the wobble arrested whilst printing

The wobble arrester works wonders, and if anyone needs to see why it is handy, check this video out of the one i installed...

with the wobble arrester installed, i made the gears.

picture too come.

firtly i decieded to change my usb ttl adapter for the makerbot to a 5v logic level, as apposed tothe 3.3v logic level one i was using. the idea behind this was that the switchover signal voltage could have been too low and therefore meant the data was not being sent at good quality. I was annoyed when i bought the first cable, as i was thinking it was a 5v level cable, but alas... oh well.

the first tests came as i was setting up the uni makerbot for a demo of high calibre... more on that in a sec, but i managed to start repg and the new software version, meaning i could import and manipulate the files stl etc in repg.

the first trial pieces were done using my pc desktop, an old pentium 4. (i now bought a i5 HP laptop, so yay!) I did wounder if the processing speed was too slow for the makerbot, and i think i might have been right...

anyway, my first prints using the 5v cable, turned out to be good. they were a corner bracket, to try simple shapes... and then the z wobble arrester. this is an amazing thing an im glad i printed it, as my sides are virtually wobble free (need a second one for other side of rear as that too is a bit wobbly...

anyhow, i printed these with great success, installed the wob arr and set to print something more complex. The gear set, recently uploaded seemd lie the perfetc vhoice.

link here :(insert link)

the results seemed ok, but the thinner smaller gear had to be height adjusted as too much plastic was comming out causing lumps. - this maybe because there wasnt enough time to cool befre the heater nozel came ploughing through, so need to work on 'cool' settings as mentioned in recent blog post elsewhere - should really write the links down!. need to adjust speed and extruder flow rate too, both adjust this issue.

right a picture...

or 2...

the L bracket, shows several wobbly edges so off to print the z wobble arrester...

the wobble arrested whilst printing

The wobble arrester works wonders, and if anyone needs to see why it is handy, check this video out of the one i installed...

with the wobble arrester installed, i made the gears.

picture too come.

Sunday, 10 October 2010

dead...

mkerbot mk4 plastruder is dead. and i dont have money to buy the mk5. uni have bought the last of my nichrome wire so i dont have the ability to rectify, therefore i have decieded to stick it in the loft and forget about it till i have money.

Monday, 27 September 2010

Release of Thing-o-matic

no relation to wallace and gromit, but makerbot have now released the next gen of makerbot! the thing-o-matic provides automatic printing with the belted buikld base and much finer resolution printing!

It is a shame the cost hasd also increased! sadly to import one of these into the UK, will cost £711 for the kit, postage about £30? then charges totalling an estimated £140, making the total cost £900... sadly i cannot afford this, but am very tempted to break open the uni laser cutter and make myself one when the files become available :D

all for now, but check out the details online:

Sunday, 22 August 2010

Solidwork developments

Thursday, 29 July 2010

Animatronic Skin and Teeth

I recently bought some Platsil Gel10 to make robotic skin from www.dauphines.co.uk they did a good price, and also sell plastic human eyes aswell - something cheap and chearfull that i could use on my larger heads.

I bought 2kg tubs of the stuff, as well as skin pigment for the silicone. that and 2 eyes came to £61.20 plus £7 postage.

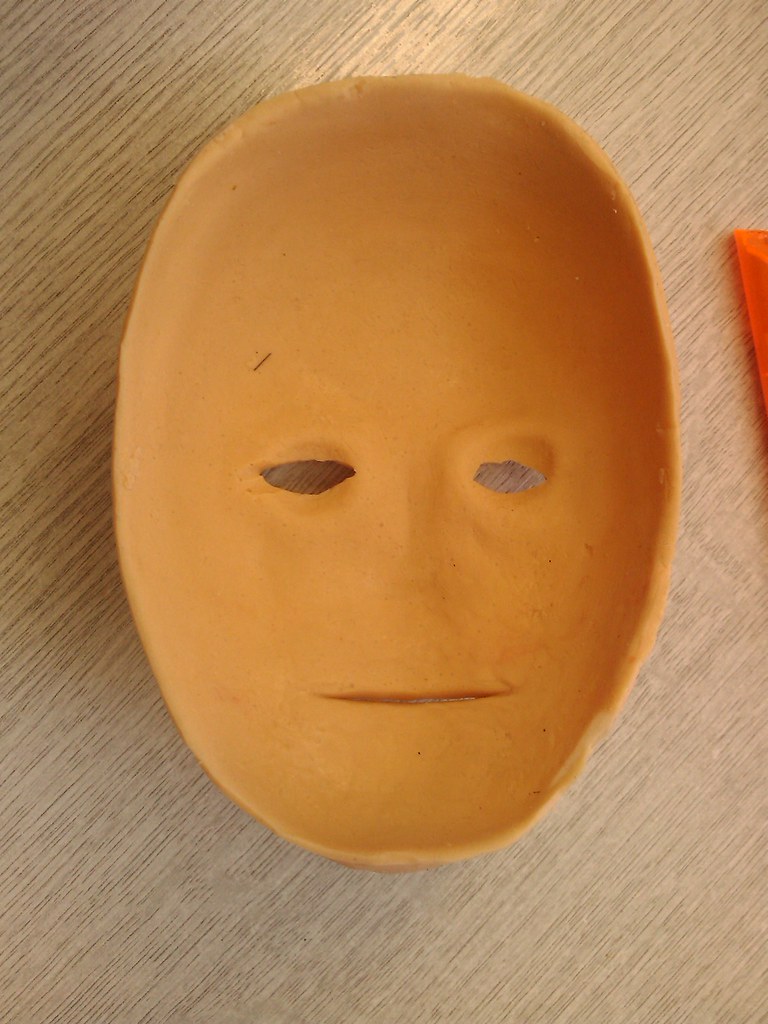

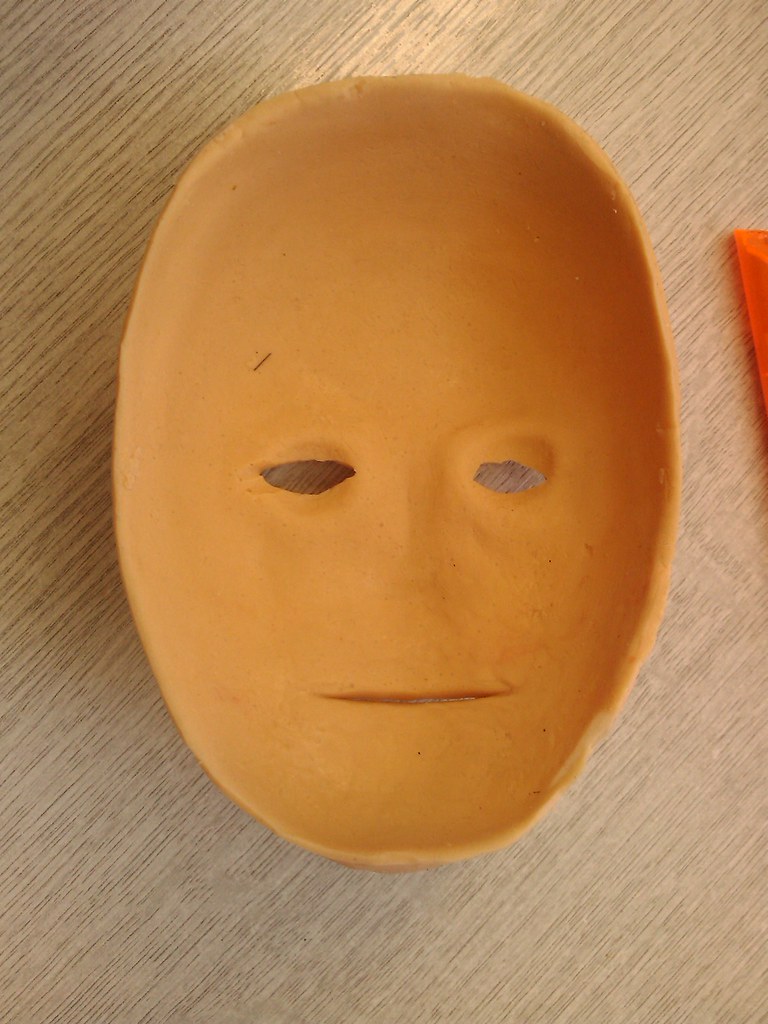

The sculpture i made was of a human head whichj is about 11-12 cm tall

here you can see the small ears i made - these are about 3cm tall.

I started off with 2 inmages from google - a portrait and a side view of a male, i resized both to the same size and then used these to cut out a wooden template. The clay was then sculpted around these 2 pieces to form the smape of the head.

this is a close-up of one of the ears. I am pleased ith this one. I didnt use any references but just feeling my own ears.

Sadly, copying this ear pattern to the other side was more difficult than I thought it would be.

This is the final head with its acrylic coating. I should have spent more time smoothing it down, but this being my first project to hopefully a good portfolio, i wanted to just get it done and see what it looked like.

i then made a mould of the glay head using fibreglass matt and sheet - using gelcoat (sadly not witht he catalyst) and built a 3 segmented mould

The next step was to make the eyes, for this i used 15cm wooden beads which i bought from the local bead-ery shop (lol)

I cut them just past half way, and hollowed out the insides of them, allowing me to fit in a ball joint (will need to change this as it allows full movem,ent not just movement in x and y.)

The servo will be mounted behind the eyes, and this is an ongoing task. - the servo seen in the picture is for the jaw.

The wooden shapes are taken from the ear-to-ear template i made for the sculpture.

The front to back piece was cut out using the rear of the mould used for the skin. This means that there is a small gap between the skin and this piece - to be made from aluminium at a later date.

This is the outer skin, it is made by layering thin clay into the negative fibreglass mould, then a layer of fibreglass is layed ontop of this.

As i did the face seperate from the rest of the head - due to my 3 part mould i made (it doesnt go over a head so i adopted a different method to Daniele Tirinnanzi )

The inner mould was made which overlapped the edge, which means i can refit the inner mould to the existing keys from the front so that it all lines up correctly.

[image to come]

The rear of the skin shows the thickness and the nose which i filled in with the silicone to create a smooth base to fit onto the metal chasis inside when i finished it.

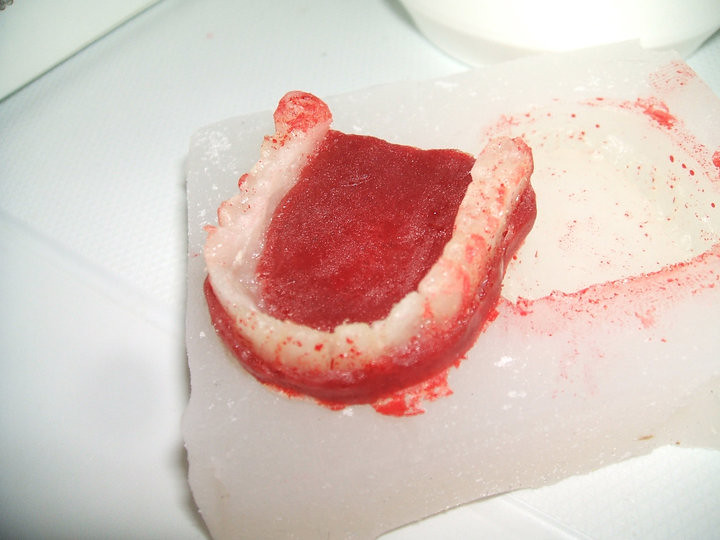

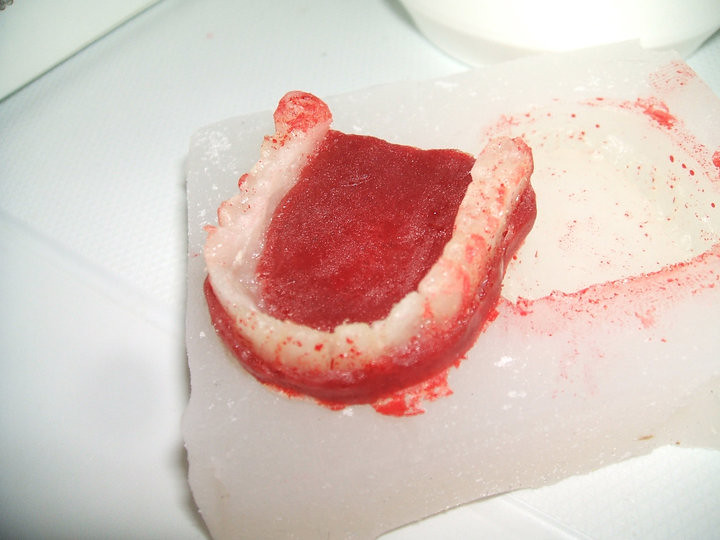

Now onto the teeth:

I purchased some dental acrylic from dentala2z which is actually used to repair dentures (if you know of better supplies, please let me know.)

This method uses powdered acrylic And a liquid (similar to acetone but smells much more potent) which melts and bonds the acrylic particles together. This creates an acrylic liquid which is pourable into the moulds.

I started off with a lump of clay, about 5mm thick, then added a bead of clay around the edge to form the teeth. The teeth were sculpted roughly – again this was my first attempt so I wanted a result, but these were actually good enough anyway. The gum lines were then sculpted into the base layer, and a silicone mould was made using platsil Gel10 (I ran out of standard silicone)

Pouring the acrylic liquid into the mould made castings of the teeth. I did this twice, then using a dremil I cut away the gum part of the casting to reveal just the white teeth.

Using food colouring, I made some more acrylic liquid and turned it red.

I placed the teeth into the mould, using a bit of petroleum jelly to seal the teeth and to stop the red acrylic sticking to parts of the teeth, I poured in the red solution.

The red gum part is a bit dark, and it also spilled onto the teeth, but because of the petroleum jelly, this was easily cleaned off - tho some staining had occoured. Next time i will be using special gum coloured dental acrylic, sadly i thought i bought white and red coloured stuff, but i hadnt. I will not be using food colouring again and i dont really recomend it!

The final teeth:

The teeth inside the skin (stretched over my hand)

So there we go, this is where i have got too.

thank you :)

nat :D

I bought 2kg tubs of the stuff, as well as skin pigment for the silicone. that and 2 eyes came to £61.20 plus £7 postage.

The sculpture i made was of a human head whichj is about 11-12 cm tall

here you can see the small ears i made - these are about 3cm tall.

I started off with 2 inmages from google - a portrait and a side view of a male, i resized both to the same size and then used these to cut out a wooden template. The clay was then sculpted around these 2 pieces to form the smape of the head.

this is a close-up of one of the ears. I am pleased ith this one. I didnt use any references but just feeling my own ears.

Sadly, copying this ear pattern to the other side was more difficult than I thought it would be.

This is the final head with its acrylic coating. I should have spent more time smoothing it down, but this being my first project to hopefully a good portfolio, i wanted to just get it done and see what it looked like.

i then made a mould of the glay head using fibreglass matt and sheet - using gelcoat (sadly not witht he catalyst) and built a 3 segmented mould

The next step was to make the eyes, for this i used 15cm wooden beads which i bought from the local bead-ery shop (lol)

I cut them just past half way, and hollowed out the insides of them, allowing me to fit in a ball joint (will need to change this as it allows full movem,ent not just movement in x and y.)

The servo will be mounted behind the eyes, and this is an ongoing task. - the servo seen in the picture is for the jaw.

The wooden shapes are taken from the ear-to-ear template i made for the sculpture.

The front to back piece was cut out using the rear of the mould used for the skin. This means that there is a small gap between the skin and this piece - to be made from aluminium at a later date.

This is the outer skin, it is made by layering thin clay into the negative fibreglass mould, then a layer of fibreglass is layed ontop of this.

As i did the face seperate from the rest of the head - due to my 3 part mould i made (it doesnt go over a head so i adopted a different method to Daniele Tirinnanzi )

The inner mould was made which overlapped the edge, which means i can refit the inner mould to the existing keys from the front so that it all lines up correctly.

[image to come]

The rear of the skin shows the thickness and the nose which i filled in with the silicone to create a smooth base to fit onto the metal chasis inside when i finished it.

Now onto the teeth:

I purchased some dental acrylic from dentala2z which is actually used to repair dentures (if you know of better supplies, please let me know.)

This method uses powdered acrylic And a liquid (similar to acetone but smells much more potent) which melts and bonds the acrylic particles together. This creates an acrylic liquid which is pourable into the moulds.

I started off with a lump of clay, about 5mm thick, then added a bead of clay around the edge to form the teeth. The teeth were sculpted roughly – again this was my first attempt so I wanted a result, but these were actually good enough anyway. The gum lines were then sculpted into the base layer, and a silicone mould was made using platsil Gel10 (I ran out of standard silicone)

Pouring the acrylic liquid into the mould made castings of the teeth. I did this twice, then using a dremil I cut away the gum part of the casting to reveal just the white teeth.

Using food colouring, I made some more acrylic liquid and turned it red.

I placed the teeth into the mould, using a bit of petroleum jelly to seal the teeth and to stop the red acrylic sticking to parts of the teeth, I poured in the red solution.

The red gum part is a bit dark, and it also spilled onto the teeth, but because of the petroleum jelly, this was easily cleaned off - tho some staining had occoured. Next time i will be using special gum coloured dental acrylic, sadly i thought i bought white and red coloured stuff, but i hadnt. I will not be using food colouring again and i dont really recomend it!

The final teeth:

The teeth inside the skin (stretched over my hand)

So there we go, this is where i have got too.

thank you :)

nat :D

Saturday, 12 June 2010

fibre glass

i went to see my technician friend at uni, and managed to aquire a load of fiberglass stuff...

glass matt (stranded stuff - bout the weaved matt from ebay)

PVA release agent

Honey wax release agent

resin and catalyis

gelcoat

so later today, my friend Caz will be comming over to assist me with some fun fiberglassing!

Yay!!!

glass matt (stranded stuff - bout the weaved matt from ebay)

PVA release agent

Honey wax release agent

resin and catalyis

gelcoat

so later today, my friend Caz will be comming over to assist me with some fun fiberglassing!

Yay!!!

Monday, 10 May 2010

Aluminium!!!

Just been to the tech stores and managed to aquire some sheet aluminium and angle bar, rods for making my very own animatronic (im going to last longer than lego) head mech!

This will form part of my animatronic mask and eye/tail mech which i will cover in latex/silicone cover moulded from oil based clay!

Cant wait!

This will form part of my animatronic mask and eye/tail mech which i will cover in latex/silicone cover moulded from oil based clay!

Cant wait!

Wednesday, 5 May 2010

mk4 plastruder mod for those with issues??!!?!

javascript:void(0)

Well, actually i think i have pioneered a new mod for the plastruder!

After about a month of unsuccessful prints with my faulty plastruder, i finally took my dremel tool to it and modded it!

The issue i was having was that the idler wheel would let the filament slip sideways off of the edge, sitting nicely in the corner and failing to budge causing a faulty print.

One of the issues that originally caused this was that the 'lid' to my timing pulley which fits onto the plastruder motor came off - it fell off after about 3 days - and that was many months ago before makerbot 100 was shipped!

i needed something to stop the filament sliding off to the side and getting into the corner.

The pulley placed on the end of the motor shaft did stop this, but eventually the force of the filament trying to escape the jaws of the pulley teeth would push the bearing out. i needed a way to fix it so that this force could not push on the outside and free itself.

My idea....

well. as i originally said, my plastruder timing belt lid had come off... my idea was to dremel the rough end of the timing pulley (so the teeth were flush to the end) rotate it round, and instead of having the bearing on last, was to swap it round. The bearing would fit first onto the motor shaft, then the pulley - but rotated so the screw threads would tighten furthest away from the motor. The idea being, as the motor would force the filament down, it could not pus to the side as it would push against the thicker part of the timing pulley - which is fixed...... lest see a picture!

here is the old setup, the end of the timing pulley had come away.

The pulley is placed on first, then the timing pulley - note i have tidied the end of the timing pulley to provide a flush flat edge - see previous photo)

In situe in the plastruder casing, the pulley and bearing fit perfectly and line up with the filament guides.

the filament is fed nicely through to the heater barrel.

hurray! filament is feeding at a great rate - motor set at 255 and no stripping of threads!

Also another mod i have added... A fan connected to the fan connector on the extruder mobo is positioned over the mosfets to keep the cooler - i will make some heatsinks but this seems alright so far!

Sadly they can be turned on/off using the fan control box on the control panel, however using the 'cool' function set in skeinforge (with values set to 0 and fan on at startup) we are able to make the software turn on the fan and leave it on for the entirety of the print and on afterward as well!

I must also add that the temperature of my heater barrel dropped always to 220, which caused some of the failed prints. i only just realised that this is a setting specified in the startup code. i have now modified this to display 240, and to remain hot at the end by modding the end.gcode file!

I have now had a successful continuous feed of abs t full pwm (255) for 10 minutes!

Maybe i can finally get to use my 12Kg coil of Black ABS!

Well, actually i think i have pioneered a new mod for the plastruder!

After about a month of unsuccessful prints with my faulty plastruder, i finally took my dremel tool to it and modded it!

The issue i was having was that the idler wheel would let the filament slip sideways off of the edge, sitting nicely in the corner and failing to budge causing a faulty print.

One of the issues that originally caused this was that the 'lid' to my timing pulley which fits onto the plastruder motor came off - it fell off after about 3 days - and that was many months ago before makerbot 100 was shipped!

i needed something to stop the filament sliding off to the side and getting into the corner.

The pulley placed on the end of the motor shaft did stop this, but eventually the force of the filament trying to escape the jaws of the pulley teeth would push the bearing out. i needed a way to fix it so that this force could not push on the outside and free itself.

My idea....

well. as i originally said, my plastruder timing belt lid had come off... my idea was to dremel the rough end of the timing pulley (so the teeth were flush to the end) rotate it round, and instead of having the bearing on last, was to swap it round. The bearing would fit first onto the motor shaft, then the pulley - but rotated so the screw threads would tighten furthest away from the motor. The idea being, as the motor would force the filament down, it could not pus to the side as it would push against the thicker part of the timing pulley - which is fixed...... lest see a picture!

here is the old setup, the end of the timing pulley had come away.

The pulley is placed on first, then the timing pulley - note i have tidied the end of the timing pulley to provide a flush flat edge - see previous photo)

In situe in the plastruder casing, the pulley and bearing fit perfectly and line up with the filament guides.

the filament is fed nicely through to the heater barrel.

hurray! filament is feeding at a great rate - motor set at 255 and no stripping of threads!

Also another mod i have added... A fan connected to the fan connector on the extruder mobo is positioned over the mosfets to keep the cooler - i will make some heatsinks but this seems alright so far!

Sadly they can be turned on/off using the fan control box on the control panel, however using the 'cool' function set in skeinforge (with values set to 0 and fan on at startup) we are able to make the software turn on the fan and leave it on for the entirety of the print and on afterward as well!

I must also add that the temperature of my heater barrel dropped always to 220, which caused some of the failed prints. i only just realised that this is a setting specified in the startup code. i have now modified this to display 240, and to remain hot at the end by modding the end.gcode file!

I have now had a successful continuous feed of abs t full pwm (255) for 10 minutes!

Maybe i can finally get to use my 12Kg coil of Black ABS!

Wednesday, 28 April 2010

my mini head can see clearly now (with clear perspex shell)

After a few weeks i recieved my new makerbot shell from uni, sadly during constructions, 2 pieces went snap, therefore i have an almost clear makerbot shell... - pics in my flickr pool!

this evening, i finally managed to get the motors soldered into place and test the thing out. The lights from the electronics illuminates the makerbot industries engraving rather nicely!

also downloaded the new ReplicatorG and tested out the new preference settings - my heated build base was not getting to the correct temp as i was using a 1mm thermistor and the 3mm settings - the extruder had a 3mm thermistor.

so i finally tested it extruding, and wow... heats up, looks very sweet and .... ah... sadly the filament stripped. need to move the idler wheel closer!

other than that, i bought a few more 5gram servos to make a small miniture animatronic head. Im designing it using sketchpad and consists of a jaw, square skull with curved pieces, eyes that move left right uop and down, and eventually eye lids - all printable on the makerbot. here is for good testing tomorrow!

over and out tonight.

Nat

this evening, i finally managed to get the motors soldered into place and test the thing out. The lights from the electronics illuminates the makerbot industries engraving rather nicely!

also downloaded the new ReplicatorG and tested out the new preference settings - my heated build base was not getting to the correct temp as i was using a 1mm thermistor and the 3mm settings - the extruder had a 3mm thermistor.

so i finally tested it extruding, and wow... heats up, looks very sweet and .... ah... sadly the filament stripped. need to move the idler wheel closer!

other than that, i bought a few more 5gram servos to make a small miniture animatronic head. Im designing it using sketchpad and consists of a jaw, square skull with curved pieces, eyes that move left right uop and down, and eventually eye lids - all printable on the makerbot. here is for good testing tomorrow!

over and out tonight.

Nat

Friday, 16 April 2010

Rats... plastic tears and wooden saviours

Last night I decided to take apart my makerbot and put it in its new shell properly.

Something’s I didn’t not take into consideration was the extra holes I made in the printer chamber base to attach the electronics, nor the fact I soldered the wires for the motor.

After cutting them, I continued to piece together the shell, sadly it didn’t quite fit resulting in the fragile plastic shell snapping in more than 3 places... as well as having the tabs snap off about 3 places.

I’m not enjoying it at all... so now I’m left with a makerbot shell snapped, a wooden shell, and a makerbots bits box that need rebuilding... fun... not.

The conclusion of the day - make the tabs bigger than the material so that it will slot in easily, or failing that...

DONT MAKE IT OUT OF PLASTIC! Wood is the way to go.

Something’s I didn’t not take into consideration was the extra holes I made in the printer chamber base to attach the electronics, nor the fact I soldered the wires for the motor.

After cutting them, I continued to piece together the shell, sadly it didn’t quite fit resulting in the fragile plastic shell snapping in more than 3 places... as well as having the tabs snap off about 3 places.

I’m not enjoying it at all... so now I’m left with a makerbot shell snapped, a wooden shell, and a makerbots bits box that need rebuilding... fun... not.

The conclusion of the day - make the tabs bigger than the material so that it will slot in easily, or failing that...

DONT MAKE IT OUT OF PLASTIC! Wood is the way to go.

Sunday, 11 April 2010

Black as night, Evil as Darthvader!

Afternoon on this glorious sunny day!

i thought i would start printing with my black ABS to see whgat it is like. and results are good!

Unfortunatly i have had a few flossing issues - but i will sort that out later.

The first thing i needed to do was to feed through the black abs. This would be odd as i have been using white ABS so it was interesting to see a fhite filament turn grey as it mixed with the black ABS.

The next thing to do ws to use my Darf Vader i had previously Skeinforged... sadly i had deleted it when i was sorting out my hard drive, thereofre i opened skeinforge and redid it. Sadly skeinforge seems to get stuck and freeze half way through the process, therefore i tried my already skeinforged piece - the clean whistle.

First results seem to be good except the raft came off the build base, therefore i had to abbort, but it looks good so far!

It was a good opportunity to see the 'pea' of the whistle up close...

Anyways i need to close down now as im going to Portsmouth for my dentist appointment tomorrow! NHS for ya! cant loose an NHS dentist! (Im currently in plymouth!)

i thought i would start printing with my black ABS to see whgat it is like. and results are good!

Unfortunatly i have had a few flossing issues - but i will sort that out later.

The first thing i needed to do was to feed through the black abs. This would be odd as i have been using white ABS so it was interesting to see a fhite filament turn grey as it mixed with the black ABS.

The next thing to do ws to use my Darf Vader i had previously Skeinforged... sadly i had deleted it when i was sorting out my hard drive, thereofre i opened skeinforge and redid it. Sadly skeinforge seems to get stuck and freeze half way through the process, therefore i tried my already skeinforged piece - the clean whistle.

First results seem to be good except the raft came off the build base, therefore i had to abbort, but it looks good so far!

It was a good opportunity to see the 'pea' of the whistle up close...

Anyways i need to close down now as im going to Portsmouth for my dentist appointment tomorrow! NHS for ya! cant loose an NHS dentist! (Im currently in plymouth!)

Friday, 9 April 2010

Inow you see it... now you dont

This is my new makerbot shell from uni - as part of there makerbot manufacturing they cut me a new clear shell and plastic x and y stages aswell :) looks very sweet!

Thursday, 8 April 2010

New toys

Today i recieved good presies

A nice 12lb coil of plastic filament in evil black

A new free makerbot shell from the spare materials from the University of Plymouth makerbot making.

I will soon transfer mu parts from my wooden case to the acrylic one just after i have got my job (interview tomorrow) and tidied everything up.

I will keep the pare bits of wood however as the acrylic may snap - a bit has already broken a tab :(

The arrival of the plastic filament will be tested tomorrow when i start to extrude some - i already have Darthvader awaiting!

Again! Thank you!

Wednesday, 7 April 2010

Comming out of its shell

On wednesday last week, i took my makerbot to my uni and showed it off to the tech dept there - they were the ones to originally cut out the shell in the first place.

Attending the demo were some technicians and the guy in charge of the faculty of engineering. He saw the makerbot and instantly asked for the uni to produce one. I did tell them they needed to make any improvements open to the community, and with a flick of a switch, its now been 7 days, and they already have a shell and parts and electronics being made on the uni PCB milling machine - LPKF machine. Its only been a week!

One thing is tho, they did buy a bit too much acrylic to make the shell from... 5mm clear perspex sheet... i went and saw it at lunch time, and showed them the way it fits togeter. then at 3pm, they said they cut me a shell out of the spare acrylic.

Sweet! a clear makerbot shell is mine... ALL MINE!!!

Pics to come tomorrow when i remember my camera...

oh and tomorrow is my job interview :(

Attending the demo were some technicians and the guy in charge of the faculty of engineering. He saw the makerbot and instantly asked for the uni to produce one. I did tell them they needed to make any improvements open to the community, and with a flick of a switch, its now been 7 days, and they already have a shell and parts and electronics being made on the uni PCB milling machine - LPKF machine. Its only been a week!

One thing is tho, they did buy a bit too much acrylic to make the shell from... 5mm clear perspex sheet... i went and saw it at lunch time, and showed them the way it fits togeter. then at 3pm, they said they cut me a shell out of the spare acrylic.

Sweet! a clear makerbot shell is mine... ALL MINE!!!

Pics to come tomorrow when i remember my camera...

oh and tomorrow is my job interview :(

Monday, 5 April 2010

SBM0001 Gets HOT under the collar

I have spent a long time trying to build a nice heated build base...

It started off with hacking a USB cup warmer (big FAIL)

then i used nichrome wire held on with kapton tape to an acrylic build base. This worked for a short while until the nichrome etched into the acrylic causing it to bend.

This is my latest solution, and one i been using for about a week and a bit now, but i wanted to wait on blogging it incase it failed too. But it hasnt!

What you need...

*Build Base with a hole in each corner (square unlike mine!)

*Double sided copper clad board (100mm x 100mm)

*Kapton tape (1 inch)

*8 M3 washers

*6 M3 nuts

*2 M3 bolts 12mm Countersunk

*2 M3 bolts 15mm minimum Countersunk

*5.5mm socket - or spanner/pliers

*screwdriver for your bolts

*100mm x 22mm Strip board tracks run longest way

*3mm and 8mm drill (countersink) bits and drill

*Nichrome wire (i used 2 old pieces i previously used for the extruder so about 6 ohms long)

*thermistor (im using 1mm but 3mm is great! (may need to sand small indent to buildbase for it to fit)

*wires

*crimps (to attach wore to nichrome)

*connectors to make it memovable (5/4 pin molex male/female)

*capacitor, connector and resistor to attach it to extruder board - as described here: plesantsoftware

Thats it... oh and soldering iron, solder... etc

Part 1, Prepare the PCB

Drill 4 holes using your heated build base as a template. these need to match up and be square so it fits the build base neatly, and allows heatness to cover the whole build area.

Now using the larger drill bit, countersink the holes so that the bolt heads are flush with the copper clad board NOTETHe photo was taken after kapton application)

Part 2. Applying the nichrome

Because i had severall attemots at the heater nozel, i have lots of spare nichrmoe without the inlator, therefore iused lot of kapton tape.

First we need to cover the BOTTOM - the bit nearest the build base, this protects from possible shorts. This meas 4 strips of kapton tape width 1 inch on the bottom then layer a second layer the other direction so there are a total of 2 layers. The important bit is that there is no overlap to the front. this is because we want the top to be flat as possible!

Once this has been put down we can l;ay the nichrome. Using the method of connecting your wire to the non solderable nichrome, just this time, add the 2 lengths of nichrome to the one wire. Then tape donn the nichrome so that it covers the whole area equally.

Next we can add the thermistor. Solder wires to the thermistor, and then attach this to the center of the board.

Then cover the whole lot in a few more layers of kapton tape.

The final step is to lay a flat layer of kapton tape onto the top of the build base... this is where you can toop the tape onto the reverse.

Part 3. The connector

This is ythe strip board where the connector is placed where you can easily unplug the build base from the cable loom.

The stripboard will be attached to the base by the longer screws, therefore you need to drill the holes into it. (see image below)

Solder the wires so that they are neat, and goto the pins of the connector. i had 2 heater wires then 2 thermistor wires. My original connector - using ethernet plugs had this different. Where the screw holes are, you need to cut the strips so that the metal nut would not short things.

Push the screws through the holes you drilled into the build base remembering the longer 2 need to be where the connector pcb is., it may be necessary to cut the kapton tape over the hole. Add 2 washers onto each of the screws then attach the build base through onto the screws (up side down remember) and so that the strip board connector goes to the side you want it (with mine i made the drill holes not equal, so it only fits one way round)

Add the nuts, so that the build base is secure. then thread on the stripboard remembering that the connector needs to face the right way. Secure with 2 nuts.

Part 4. The cable loom.

The final step is to connect the connector made using the Pleasentsoftware method (link above) and to attach it to the build base.

Change the settings for replicatorG, and skeinforge - the Chamber setting!

Connect the thermistor to the extruder board, and the heater wire to the A- and A+ connector, let it heat up and enjoy flat printing!

This is thing 932, my makerbot mini i designed! Makerbot Minihttp://www.thingiverse.com/thing:932

Arms, courses and welding

Hi fellow people!

well its been a while since i updated this blogspot, an in a way quite a bit has happened...

I went to speak to a lecturer in Hertfordshire Uni as i really want to get into animatronics, and the skills i learnt on my Robotiocs BSC and MRes course didnt quite get me there, so im now looking at the MA special effects course, Which is REALLY interesting!

After speaking to the lecturer, he offered me an Unconditional MA place with first year and second year modules as part of that! Therefore im going to learn the skills envolved with skinning a robotic arm etc...

This is me at the end of my BSc robotics with my robotic arm... not quite ready for tv, but thats the skills i need to gain, so i need to save money! however...

This is me at the end of my BSc robotics with my robotic arm... not quite ready for tv, but thats the skills i need to gain, so i need to save money! however...

I have applied for some funding but i think that has failed :(

anyways! i did say that it will probably be next year i will attend, as i need to save £8500 just forthe tuition fees, and bearing in mind that this will be in Hatfield 0 near london, prices do start to increase!

BUT yay!

The next thing is that i have started a welding course -City of Guilds Level 1 in TIG welding. Am hoping to use this skill when i do large scale animatronic builds - and should make me more employable in said field :)

Thirdly... which i will blog shortly is my makerbot! I have finally workid out my heated build platform for my makerbot... using Kapton tape, FR4 PCB clad board and Nichrome wire :) - Will blog about this shortly so i can lnk it on thingiverse.

4thly, i have spoken to a specialist regarding my broken wrist... (yes i badly broke my wrist as i was walking tothe doctors... i tripped on roken pavement and caught my wrist ona railing.) havetohve a rebake as it is badly clicking...

right now to blog my heated build base :)

well its been a while since i updated this blogspot, an in a way quite a bit has happened...

I went to speak to a lecturer in Hertfordshire Uni as i really want to get into animatronics, and the skills i learnt on my Robotiocs BSC and MRes course didnt quite get me there, so im now looking at the MA special effects course, Which is REALLY interesting!

After speaking to the lecturer, he offered me an Unconditional MA place with first year and second year modules as part of that! Therefore im going to learn the skills envolved with skinning a robotic arm etc...

This is me at the end of my BSc robotics with my robotic arm... not quite ready for tv, but thats the skills i need to gain, so i need to save money! however...

This is me at the end of my BSc robotics with my robotic arm... not quite ready for tv, but thats the skills i need to gain, so i need to save money! however...I have applied for some funding but i think that has failed :(

anyways! i did say that it will probably be next year i will attend, as i need to save £8500 just forthe tuition fees, and bearing in mind that this will be in Hatfield 0 near london, prices do start to increase!

BUT yay!

The next thing is that i have started a welding course -City of Guilds Level 1 in TIG welding. Am hoping to use this skill when i do large scale animatronic builds - and should make me more employable in said field :)

Thirdly... which i will blog shortly is my makerbot! I have finally workid out my heated build platform for my makerbot... using Kapton tape, FR4 PCB clad board and Nichrome wire :) - Will blog about this shortly so i can lnk it on thingiverse.

4thly, i have spoken to a specialist regarding my broken wrist... (yes i badly broke my wrist as i was walking tothe doctors... i tripped on roken pavement and caught my wrist ona railing.) havetohve a rebake as it is badly clicking...

right now to blog my heated build base :)

Monday, 25 January 2010

Contact companies, people regarding animatronics jobs.

Jonathan Nolan: http://www.johnnolanfilms.com/animatronics/ - Worked alot at Crawley Creatures, also on Agent Crush film.

Email about tyope of design work - programming? america?

Email about tyope of design work - programming? america?

Monday, 18 January 2010

Milling a PCB with a makerbot

Well, time has come to write stuff up!

Making a pcb with the makerbot has been my task for the last couple of months, and i have had experienced some issues... but happy times.

Making a pcb with the makerbot has been my task for the last couple of months, and i have had experienced some issues... but happy times.

Friday, 15 January 2010

ptfe issues

Well fun times I mustsay, my order part decided to fail so I can't use my makerbot at the. moment. I have a rod of ptfe but no time to make it. That's war u get for working lol. Any ways, I will make one soon so I cam start to print again

However one thing i have been looking at id converting makerbot into a PCB mill. The idea being I can take out the plastruder and add on the dremil fitting and cut circuit boards. This has led me to think about mak8nguyen a laser cuttablw cnc using the same electronics from makerbot possibly letting makerbot make and sell for a small return for me. We shall see. So far I have mote stepper nema17 and a larger nema 23 and rods from printers with a polystyrene mock up. So far looks like I can have a board build base of about 250 x 300. Fab! Pics tp come. I'm currently updating web site whilst waiting for my friend at Plymouth train station

However one thing i have been looking at id converting makerbot into a PCB mill. The idea being I can take out the plastruder and add on the dremil fitting and cut circuit boards. This has led me to think about mak8nguyen a laser cuttablw cnc using the same electronics from makerbot possibly letting makerbot make and sell for a small return for me. We shall see. So far I have mote stepper nema17 and a larger nema 23 and rods from printers with a polystyrene mock up. So far looks like I can have a board build base of about 250 x 300. Fab! Pics tp come. I'm currently updating web site whilst waiting for my friend at Plymouth train station

Friday, 1 January 2010

Happy new year

happy new year to you all, well those few if qny who read this blog lol.

i just wanted to update my makerbot progress, however this again will be short as im using a french keyboard and i hate typing on it - it hiurts my wrist badly

well i have had sucess on pcb making and made an opto sensor, i will write about it when i; back in plymouth as i am currently in holland.

wrist really hurts!!

i just wanted to update my makerbot progress, however this again will be short as im using a french keyboard and i hate typing on it - it hiurts my wrist badly

well i have had sucess on pcb making and made an opto sensor, i will write about it when i; back in plymouth as i am currently in holland.

wrist really hurts!!

Subscribe to:

Posts (Atom)